SƠN CHỐNG CHÁY 2 GIỜ

( Sơn chống cháy 120 phút gốc sơn dầu )

Mục đích sử dụng : Sơn phồng một thành phần sử dung cho hệ sơn chống cháy 2giờ

Hạn chế : Không sử dụng cho mục đích khác ngoài mục đích trên

Thông tin nhà phân phối: Công Ty Đại Mộc Thủy

Địa chỉ sản xuất nguyên liệu : Wanju_Gun, Jeollabuk-do, Korea

Định mức sử dụng chống cháy:

-

Chống cháy chịu được 2h (120 phút) sơn 1lít= 0,28 m2

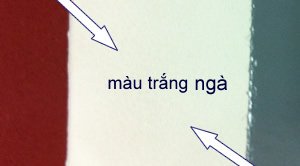

Màu sắc: Màu trắng ngà như hình

Khi có lửa cháy sản phẩm này phồng nở lên gấp 10 lần độ phủ dày của lớp sơn, Nó không bị cháy mà chỉ có hiện tượng bốc khối.

Có tất cả tài liệu, thông số kỹ thuật, chứng chỉ của tập đoàn Hàn Quốc

INTUMESCENT PAINT FIREMASK SQ-250(V)

Intumescent paint FIREMASK SQ-250(V) is a middle coat in solvent-borne anti-fire paint to provide fire-protection of plants or facilities that have a steel construction and handle flammable materials.

This product is approved with its superior heat insulation ability by Korea standard tes for up to 150-minute intumescent paint.

Recommended use Middle-coat for in anti-fire paint to provide fire-protection for plants or facilities having steel construction.

PHYSICAL PROPERTIES

Finish and Color: Flat / White

Drying Time:

|

5°C |

20°C |

|

|

Set to touch |

5 h |

2 h |

|

Dry hard |

24 h |

12 h |

The actual drying time is subject to the film thickness, ventilation, humidity etc., and drying time under other temperature conditions must be checked and informed from us.

Non Volatile ratio: 75% ± 2%

Spreading Rate (Theoretical): 1.25L/m2 in 800 microns dry film thickness on a smooth surface.

Specific Gravity: Approx. 1.25 (Kg/L)

Flash Point: 25°C (hermetically)

APPLICATION DETAILS

Surface Preparation

* Remove old paint film, dust, oil and grease, other contaminants.

* As a rust protective primer:

Epoxy based primer KOREPOX PRIMER EP170, EP1760 Red-lead based paint KSM6030(Class 1)

INTUMESCENT PAINT FIREMASK SQ-250(V)

Alkyd based primer

Inorganic zinc primer GALVANY IZ180N,

Organic zinc primer KOREPOX ZINC RICH PRIMER EZ175.

* If GALVANY IZ180N is applied as primer, mist coat will help to avoid popping of the subsequent coat.

– As a mist coat : EP170QD (DFT : approx. 40pm)

Application Conditions

The surface must be completely clean and dry.

Do not apply when relative humidity is above 85%.

The surface temperatures must be at least 3°C(5°F) above dew point to prevent condensation.

Thinning

Summer season(THINNER No.002),

Winter season(THINNER No.003) Apply after mixing for 5 min. with Hand-Mixer (above 200rpm)

Methods of Application

Brush, Roller and Spray ( air or airless ) application.

For airless spray application ;

- Nozzle orifice : 0.027″ ~ 0.033″

- Output pressure : 1,800 ~ 2,200 psi / 120 ~ 150 atm.

- Fan : 30°~ 60°

- Thinning : Max. 3% by volume

- (Airless spray data are indicative and subject to adjustment.)

Film Thickness

Recommended per coat <1350 microns wet film thickness

Recoating Interval

At 20°C/68°F, below 80% R.H, under well-ventilated condition

Minimum : 24 hours

In highly humid conditions(ex. In heavy rain), recoating interval can be extended as delayed period.

Subsequent Coat

KORABOR ENAMEL RT546, urethane topcoat, epoxy topcoat, alkyd topcoat, acrylic topcoat or according to specification.

Top coat must be applied after 3 days(in summer) and 7 days (in winter) of the last mid-coat spay. Impossible for exterior Application. (If unavoidable, inquire of our company).

|

FIREMASK SQ-250(V) |

|

|

Shelf Life |

12 months (Store in dry, well-ventilated place, 5 ~ 35°C) |

|

Packing Unit |

18 L |

|

Remarks |

Avoid the cause of fire and direct sunlight during storage. Apply after adequate mixing. Protect skin and eyes, and avoid prolonged breathing of Solvent Vapors. Use with adequate ventilation. Respiratory protection is recommended when applying unconfined spaces or stagnant air. Sagging may occur in case of excessive thinning. Keep containers closed when not in use. Keep coating utensils after washing several times with Thinner. |

|

Issued |

Sept., 2018 |